FIRST STEP

Grinding

The materials (silica, kaolin, feldspar, mud) are extracted from mines in the region, they are put to dry and later they are mixed in a hammer mill, which pulverizes them, transforming them into a fine powder.

SECOND STEP

Pasta preparation

The powdered paste is mixed with water and subsequently placed in gypsum tubs to dry and can be turned, or it is kept in a liquid state (slip) for the casting process.

THIRD STEP

Turning

The dough is kneaded with the snail technique to eliminate air bubbles, then it goes to the lathe in which round pieces are made, from miniatures to large pieces such as vases or tibores, which are left to dry until they acquire the hardness of leather for later give them the final finish in the return, where excess paste is removed and edges are rectified, handles, knobs, etc. are glued.

FOURTH STEP

Emptied

The slip is emptied into the plaster mold, where it will begin to dry and form the piece, once it acquires the appropriate thickness (4 to 5 mm) the remaining slip is emptied and the piece is allowed to dry until it reaches the hardness of leather to be able to open the mold and remove the formed part.

FIFTH STEP

Rectified

Once the pieces are dry, they go on to grinding, in which edges and burrs are eliminated to give the piece a better finish.

STEP SIX

Polished and enameled

Once free of edges, the piece is polished with water and a sponge to give it a smooth finish and remove dust, then a layer of enamel is applied on the inside to make it waterproof and that it can contain liquids.

SEVENTH STEP

Marked

The marking consists of painting colored lines with a brush to the piece in the mouth, handles and knobs and later drawing a grid with pencil to the piece so that it serves as a guide for outlining.

EIGHTH STEP

Profiling

Profiling consists of dressing the piece with the decoration, this is done in cobalt blue or brown, and a knob is used, which works like a pencil, gradually releasing the color. Each piece is unique, since it is the profiler that decides how to decorate the piece, based on only a grid.

NINETH STEP

Filling

Once the piece has the decoration, it passes to the filling, which consists of filling the piece with color, the decorators combine the different colors, applying flowers, dots and filling the decorations.

STEP 10

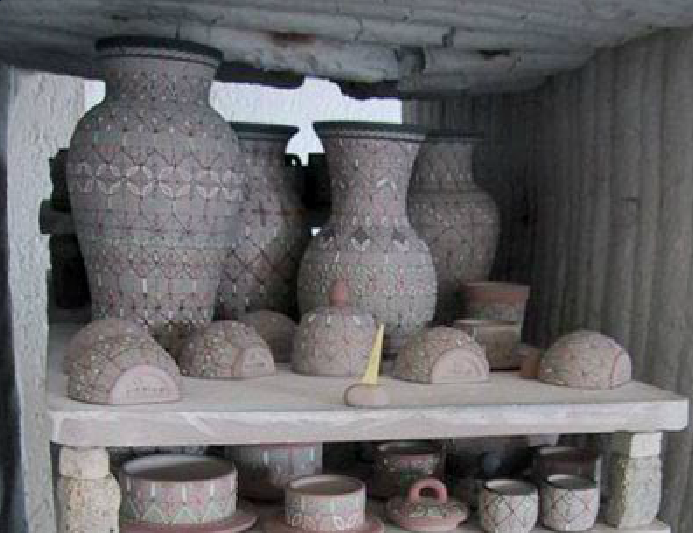

Baked

Una vez terminado el decorado, la pieza pasa al horno, en el cual permanecerá por un periodo de 8 horas a una temperatura de 1260°C. Durante este tiempo, la pieza, que antes de hornearse es frágil, adquiere resistencia y los esmaltes se vitrifican, adquiriendo un brillo característico.